Heating and Drying Cabinets HeatEvent

Product information

Heat it.

Weiss Technik is a global leader in providing advanced heat technology solutions across a wide range of industries, including microelectronics, e-mobility, plastics, and healthcare.

Our cutting-edge solutions, such as environmental test chambers and industrial ovens, are designed to deliver precise temperature control and uniformity. These solutions are essential for product development, quality assurance, and material testing, enabling companies to meet strict industry standards while optimizing performance and reliability.

Product information

Overview brochure

Product brochure

Product brochure

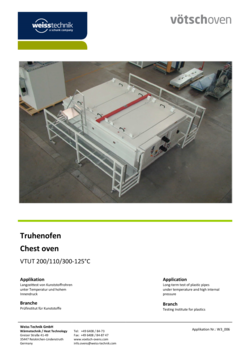

Case Study

Case Study

Case Study

Case Study

Contact

Simply fill out the form now. We'll get back to you shortly and answer all your questions.