Weiss Technik UK's Dedicated Service Team

Advanced testing, expert support

Weiss Technik UK is proud to be the leading service provider for environmental simulation in the UK, backed by a nationwide team of 16 highly skilled engineers. When you invest in one of our environmental test chambers, you can tailor the support package to meet your specific maintenance and servicing needs. With a dedicated office-based contacts and in-house technical support team, you’re never without expert assistance when you need it most.

We also offer a comprehensive range of service solutions, including maintenance, repairs, calibration and upgrades. With genuine OEM spare parts available for Vötsch, Envirotronics, Fitotron, Design Environmental, and Gallenkamp test chambers, you can trust us to keep your equipment running at its best.

Choose Your Service Package

Service solutions to meet your specific needs

Maintenance and service contracts – make service costs predictable

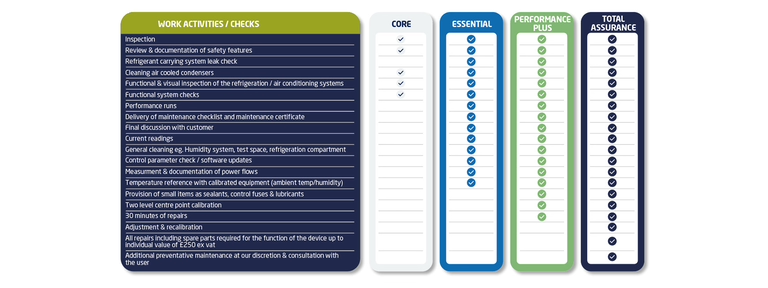

Environment simulation systems are extremely complex pieces of equipment, and they need to be maintained according to varying requirements to ensure the integrity of the original installation is maintained. For this reason, we offer graduated services where customers can choose between:

Core

Allows for one maintenance visit a year that includes all basic functional operations and safety checks and a certificate for the work carried out. Provides customer with 5% discount for labour and 10% off any parts purchased for duration of contract.

Essential

Provides you with one maintenance visit a year that includes additional checks, refrigerant leak checks and performance runs. A temperature /humidity reference point measurement, checklist and a maintenance certificate will be issued. Provides customer with 10% discount for labour and 10% off any parts purchased for duration of contract.

Performance Plus

Our most popular option that delivers total peace of mind. As part of the two visits a year a chamber calibration is carried out at 2 temperature / humidity set points, performance runs and a maintenance and calibration certificate will be issued. Provides customer with 10% discount for labour and 25% off any parts purchased for duration of contract.

Total Assurance

Allows customers to specify a precise level of service support to meet their business needs. Includes two breakdown call out days. Labour is discounted by 10% and parts by 35% off the list price. Subject to eligibility.

Here to Support You

Our service team is located nationwide, with engineers on the road, dedicated office admin and in-house technical support available to keep your operations running smoothly.

We also offer tailored training for your on-site engineers, ensuring they can maintain and operate your equipment with confidence and precision.

Contact

Do you have any questions or would like expert advice?

Simply fill out the form now. We'll get back to you shortly and answer all your questions.