Avid are experts in advanced thermal management and vehicle electrification. They are active in several markets and have a range of products from Electric Motors, ePumps, eFans, Battery systems, Thermal systems and custom solutions for Tier 1 suppliers to the automotive industry.

As with most products designed and manufactured today and especially in the automotive industry, stringent and rigorous environmental testing needs to be carried out. With the objective of enhancing the in- house testing capabilities, Avid reached out to several vibration system and climate chamber manufacturers for solutions to their test requirements.

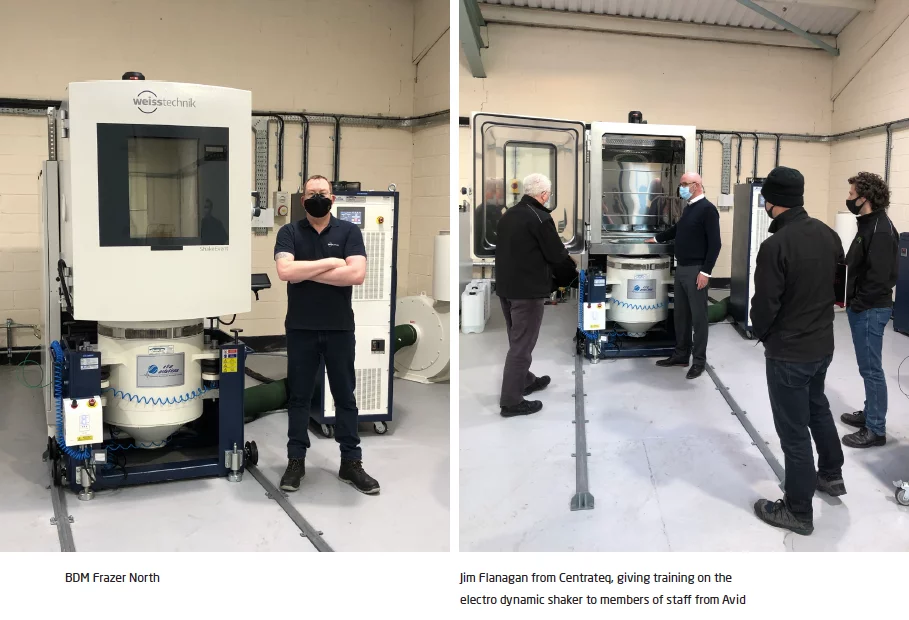

The initial brief for Weiss Technik UK was for a thermal shock chamber and a climate chamber for use with an electro dynamic vibrations system (shaker) to meet certain automotive test standards. Whilst these are standard products for Weiss Technik the integration with the shaker can sometimes be challenging and cause site issues if all the bases aren’t covered. The exact requirements for the combined vibration equipment were discussed by Jim Flanagan from CentraTEQ and Frazer North from Weiss Technik UK.

Having many previous projects of this type under our belt for exactly this type of installation, Weiss Technik offered a turnkey solution for the entire project.

Avid are experts in advanced thermal management and vehicle electrification. They are active in several markets and have a range of products from Electric Motors, ePumps, eFans, Battery systems, Thermal systems and custom solutions for Tier 1 suppliers to the automotive industry.

As with most products designed and manufactured today and especially in the automotive industry, stringent and rigorous environmental testing needs to be carried out. With the objective of enhancing the in- house testing capabilities, Avid reached out to several vibration system and climate chamber manufacturers for solutions to their test requirements.

The initial brief for Weiss Technik UK was for a thermal shock chamber and a climate chamber for use with an electro dynamic vibrations system (shaker) to meet certain automotive test standards. Whilst these are standard products for Weiss Technik the integration with the shaker can sometimes be challenging and cause site issues if all the bases aren’t covered. The exact requirements for the combined vibration equipment were discussed by Jim Flanagan from CentraTEQ and Frazer North from Weiss Technik UK.

Having many previous projects of this type under our belt for exactly this type of installation, Weiss Technik offered a turnkey solution for the entire project.

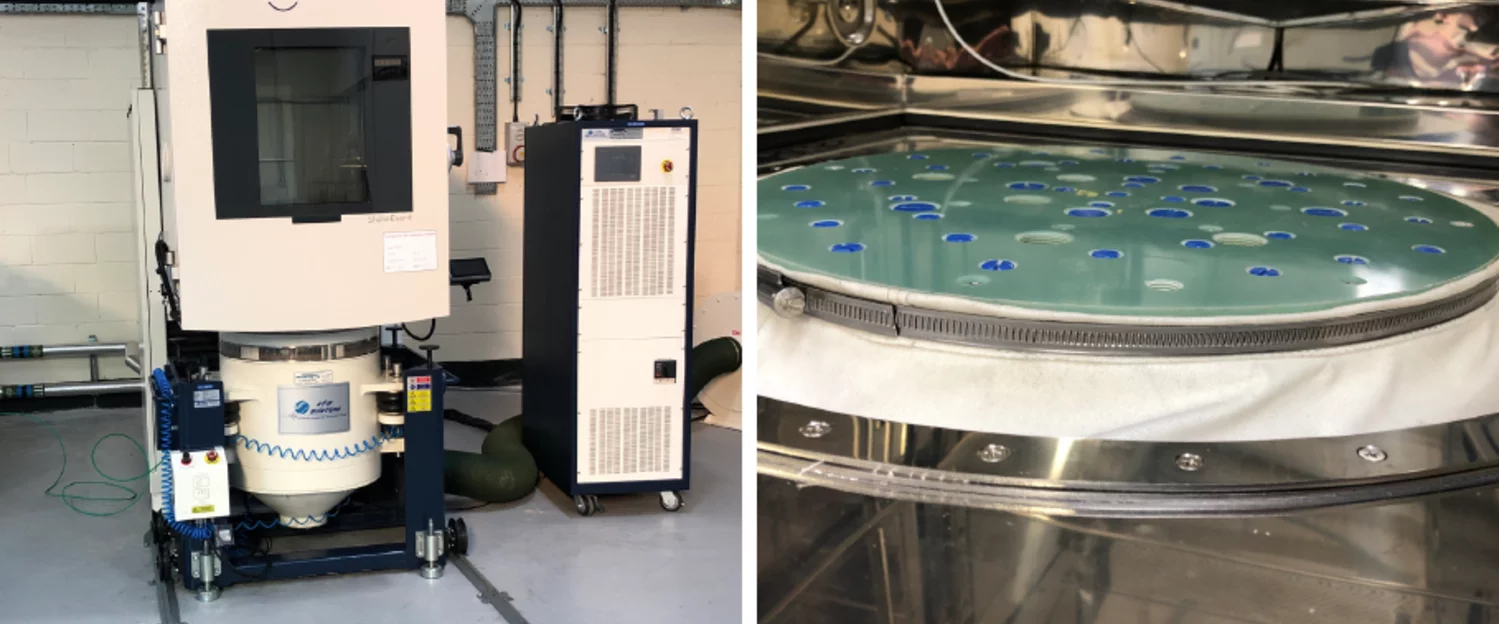

This included the supply of Weiss Technik ShockEvent and ShakeEvent chambers, an ETS Solutions electrodynamic shaker supplied by Centrateq, an M&P vibration controller and a water chiller unit for the chambers, supplied by ICS Cool Energy. All these were supplied by Weiss Technik who undertook the project lead and also managed the delivery, installation and commissioning.

Avid’s Finance Director Chris Parker commented, “The turnkey solution from Weiss Technik UK was a blessing. Dealing with only one supplier for the complete project saved a lot of time, effort and, overall, gave Avid peace of mind that the project would run as planned and most importantly, that all equipment would interface correctly. Other suppliers were unable to offer this and, with the technical solution offered by Weiss Technik, it was the ideal solution for Avid”.

That’s not to say the project was without its hiccups! A pandemic and a few changes to the installation location introduced a slight delay but the project was delivered and handed over to Avid on Friday 6th November 2020. The location and program were overseen by Chris Morton and Thanos Alexakis from Avid, both being very helpful in organising access, offloading and arranging the site services.

With all major equipment elements in place, installation of the pipework and commissioning of the water chiller was first. This was carried out by the Northern office of ICS Cool Energy with pipework thermal insulation and cladding by EcoLag.

Jim Flanagan from Centrateq, Ian Black from M&P along with Iain Rich and Andy Pink from V Tech were next on site for the installation and successful commissioning of the vibration system. This was quickly followed by Weiss Technik’s Dave Archer and Peter Bennet from the Service team and Business Development Manager Frazer North, who was also on site to assist with network cable installation and the vibration interface seal. Andrew Williams, program delivery manager, was also on site for the final commissioning to oversee any final points and ensure project completion and sign off.

Matt Lamb, Design and Test engineer at Avid, along With Dave Smurthwaite Project Lead, are both looking forward to working with the new equipment to enhance their test capabilities.

Further growth of the Cramlington-based firm is predicted over the coming years as it picks up further investment and some prestigious awards along the way. Certainly a company for the Automotive industry to keep an eye out for.