Vindur® Turnkey Clean Rooms for pharmacies

Industry brochure

Cool it.

Weiss Technik UK offers an array of cleanroom solutions and air solution systems, providing you with reliable equipment that ensures a clean environment for working and operating under optimal climatic conditions.

Our cleanroom and air solutions are also used in industrial production processes, in IT and telecommunications technology, pharmaceutical and medical settings where hygienic environments are necessary for humans and equipment.

Industry brochure

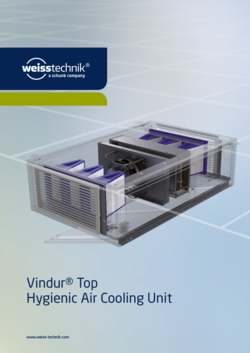

Product information

Product brochure

weisstechnik implements customer-specific new development for

mobile switching stations

Case Study

Case Study

Contact

Simply fill out the form now. We'll get back to you shortly and answer all your questions.